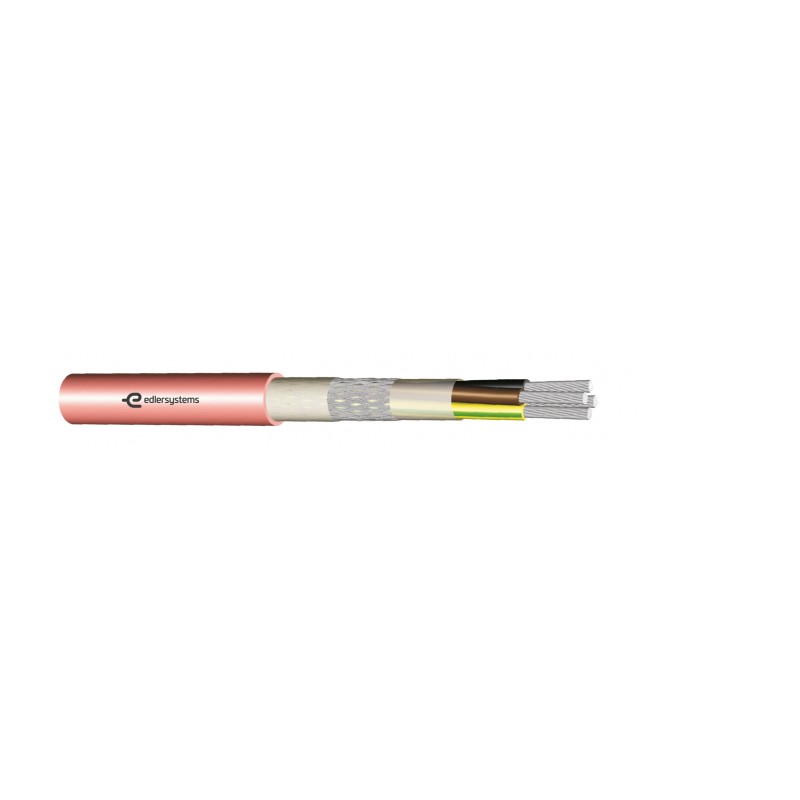

SiFCuSi

As a connection cable for low mechanical loads and high ambient temperatures, e.g. in smelters and steelworks, but also in cold environments. The insulation is based on silicone rubber. It is resistant to vegetable and animal fats, many oils and diluted acids as well as decomposition by alcohols,

plasticisers, alkalis, salt solutions, etc. If the cable is burnt, an insulating silicon dioxide layer remains on the conductor, which can prevent a short circuit. The high shielding density guarantees interference-free transmission of signals or pulses.

Download datasheet (SiFCuSi)